Introduction

The Shimen Reservoir has been in operation for more than 50 years since the 1953 of the Republic of China. After many typhoons, a large amount of soil and sand entered the reservoir, causing nearly one-third of the reservoir capacity to silt up. To maintain the reservoir capacity, the Executive Yuan announced on September 1, 2013 The Amping anti-silting tunnel project was approved, and the project construction was carried out from 107 to 110.

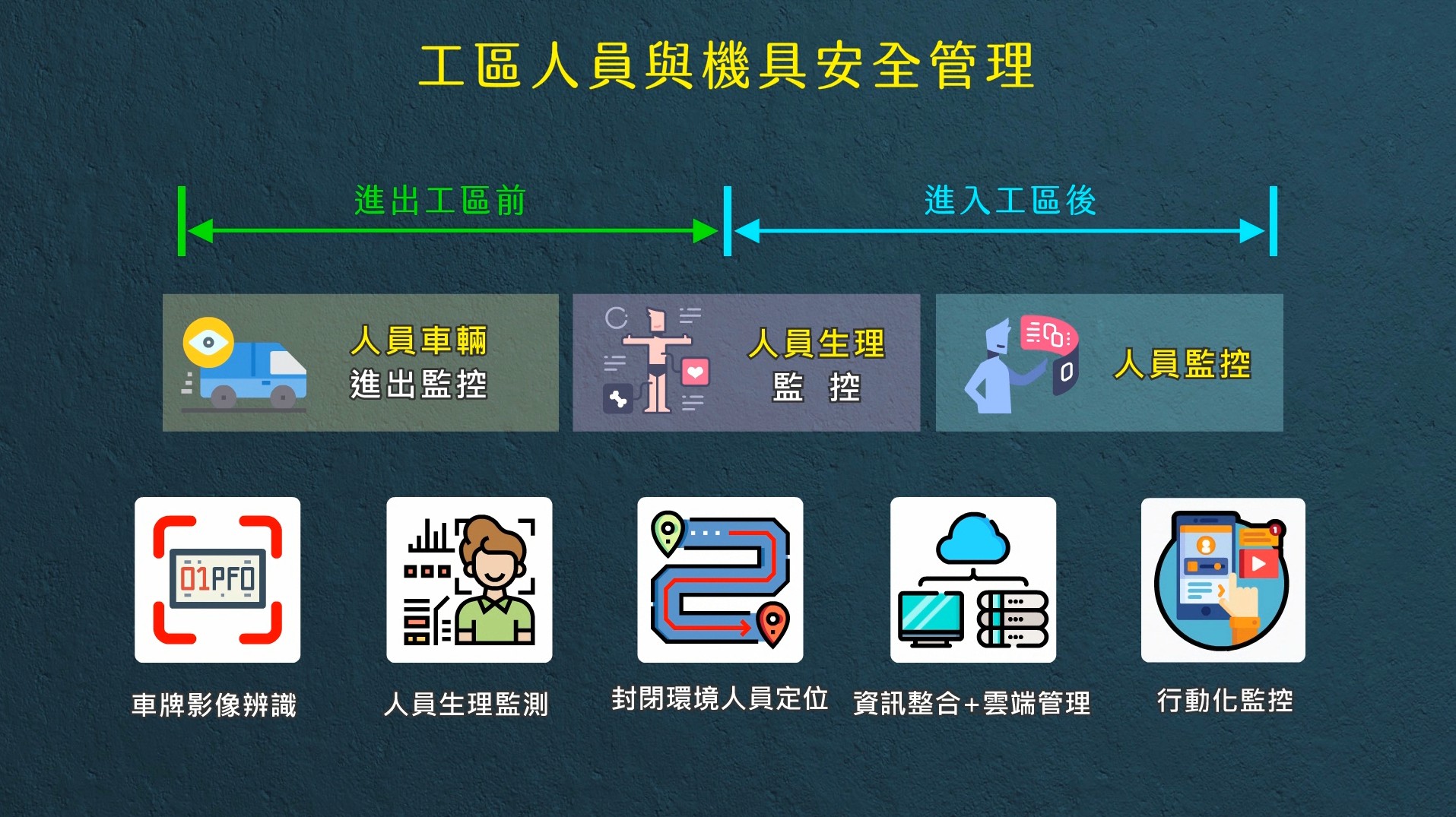

Because the tunnel is a closed and dynamic working environment, it is difficult to grasp the construction safety and sanitation conditions. To effectively reduce the occurrence of occupational accidents, it is the first to use intelligent management methods such as monitoring equipment and information and communication technology to monitor and automatically judge in real-time during the tunnel construction process. Interpret and analyze, record, and report to relevant personnel in real-time, and use current technology equipment to build a technology-based safety management mechanism to ensure the safety of labor operations.

Project performance and benefits

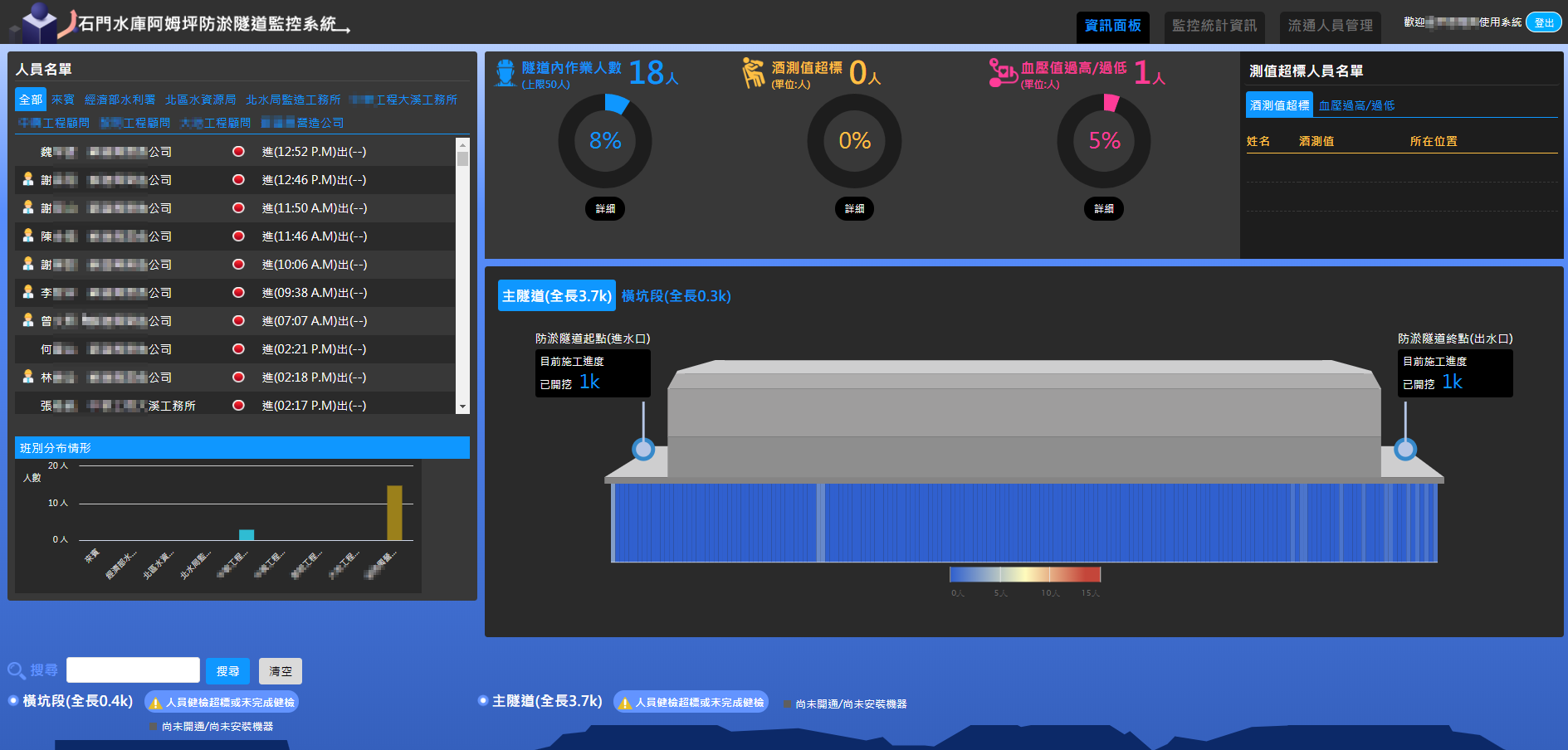

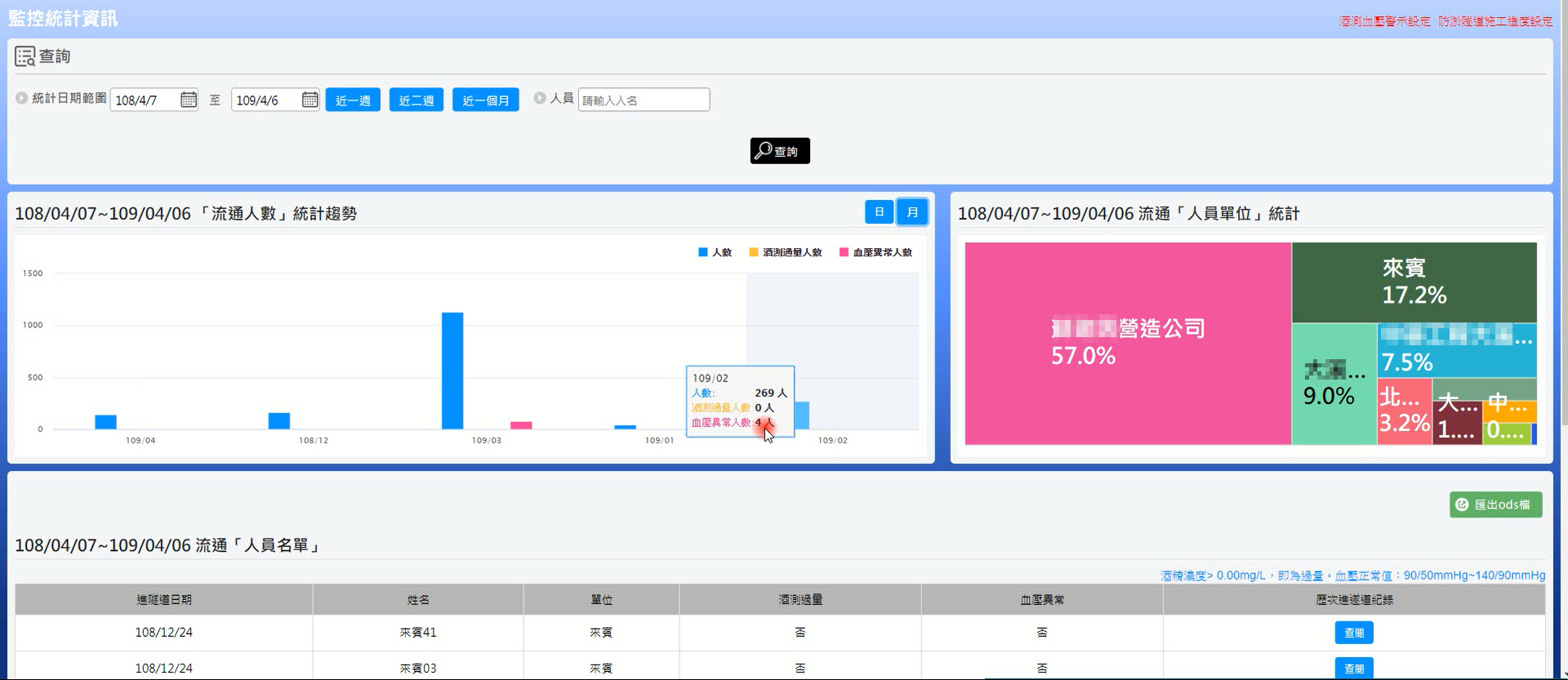

"Shimen Reservoir Amping Anti-silting Tunnel Smart Management Application Platform" adopts cross-platform development technology, and both desktop computers and mobile phones can present real-time information in the best visual way. The platform display takes personnel safety as the main axis of management, covering the time when operators enter and exit the tunnel, information of each work shift in the tunnel, personnel distribution points and personnel physiological monitoring information, etc., and displays them in the form of map visualization and table lists, which is beneficial to project management personnel and Decision makers have information on the work area.

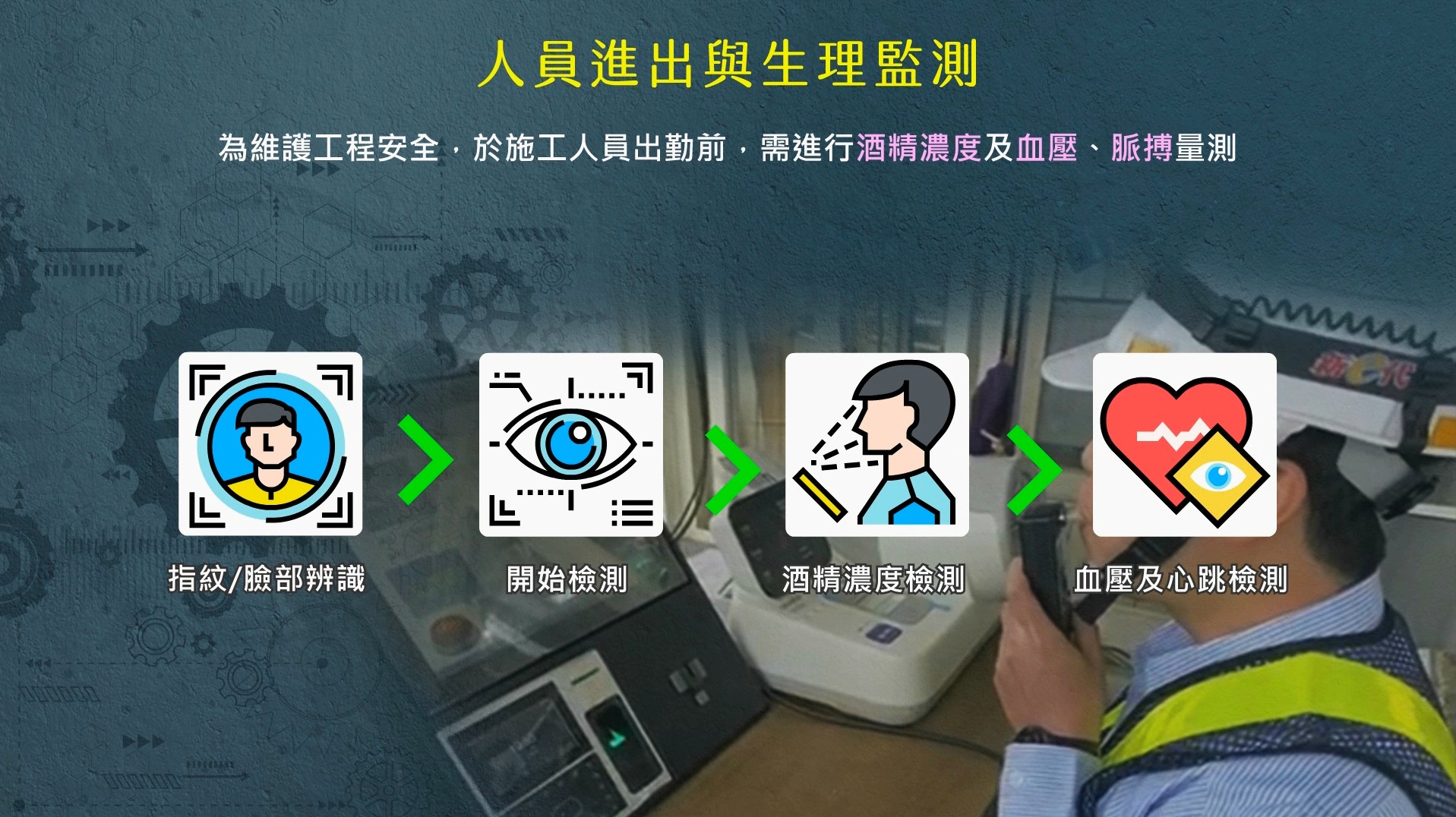

Before going to work, engineering personnel must use intelligent physiological monitoring equipment to measure alcohol concentration, blood pressure, and pulse. At the same time, face recognition technology is used to identify the personnel's identity, accurately grasp the mental and physical status of the staff, and reduce the risk of accidents.

When entering the tunnel, the safety helmet worn by the personnel has been integrated with a microsensor. During the operation, the position of the personnel in the tunnel will be continuously transmitted through Bluetooth positioning technology. When the physiological condition of the staff is abnormal, an abnormal message can be displayed on the monitoring platform to notify The management personnel of the work area and further carried out safety protection treatment.

To effectively reduce the occurrence of occupational accidents, the introduction of scientific and technological innovative management technology can obtain relevant information in real-time to control the work area, to reduce the burden of front-line colleagues and work area inspections, and provide the Water Resources Department with real-time information on the work area through high-tech monitoring. To achieve the management objectives of safety first and prevention first.